Page 1 of 2

tight fit, rought edges everywhere

Posted: 16 May 2016 18:32

by sheepherder

The R92 .45lc in SS I just purchased was a real %@*&$ to deal with. Took it apart to clean the packing grease and see how the mechanism worked.

Taking it apart based on utube videos was not too bad. The problem was the tight parts, especially the bottom tang. As those who have put a R92 back together you know the 'move' to hold the hammer, pull the trigger and push the tang to capture the hammer spring rod is hard at best. Every time I missed, I had to tap the lower tang out it was so tightly fit.

Question, is this typical? I spent 2 hrs after the fact polishing with Flitz. Helped a lot but the last 1/8 inch is still hard. The videos I have seen seem to have very easy fits compared to my low er tang.

Should I keep working on it or just let it go and not break it down to that point? A related question, after shooting, do most not take it down and just swap the inside of the receiver and NOT take down and cleant the bolt?

Also how much difference does a reduced power new hammer spring make? Cut it back or buy a after market?

Sheepherder

Re: tight fit, rought edges everywhere

Posted: 16 May 2016 18:46

by zippy

It's not just you. My husband and I spent two hours on that same bit of final assembly, the one and only time we took it apart. And no, we are not doing that again until we have to. A quick wipe with Hoppes is all it gets after shooting.

Re: tight fit, rought edges everywhere

Posted: 16 May 2016 19:23

by Archer

I haven't taken any of my 3 apart yet. So far they seem to have come out of the box pretty good and worn in fine. I MIGHT want to take some of the edges down a mite when and if I take them apart but for now they are pretty darned good. Several folks who've looked them over have asked what I did to get them so smooth. 1) they started out good. 2) I cycled them 1000 times cleaning them about 3 times in the interval and lubricating them.

Re: tight fit, rought edges everywhere

Posted: 16 May 2016 20:20

by akuser47

Pretty common Now just shoot her till she's broken in.

Re: tight fit, rought edges everywhere

Posted: 16 May 2016 23:16

by HarryAlonzo

As for cleaning, yes, I typically just brush what I can reach in the receiver. Every so often, I remove the wood and give it a good dousing top to bottom with Non-chlorinated brake cleaner. I learned this technique from Stevesgunz. Repeat until it runs clear. Stand upright until bone dry. Lubricate liberally with an aerosol lubricant of your choice (WD-40 has many detractors, but it's up to you). Stand upright overnight. Wipe down, reassemble and enjoy. Welcome to the forum!

Re: tight fit, rought edges everywhere

Posted: 17 May 2016 02:22

by barracudadave67

I had the same problem on my new .44 mag. I just took a fine honing stone, and stoned it till I had a small amount of friction on assembly, made4 assembly a little easier. Gonig to the range tomorow, withit for the first time.

barracudadave67

Re: tight fit, rought edges everywhere

Posted: 17 May 2016 05:40

by GasGuzzler

sheepherder wrote:Also how much difference does a reduced power new hammer spring make? Cut it back or buy a after market?

It's noticeable but I would not cut it or pay for a replacement. I shimmed mine with two layers of brass made from flattened .22 cases.

Re: tight fit, rought edges everywhere

Posted: 17 May 2016 08:34

by Ranch Dog

barracudadave67 wrote:I had the same problem on my new .44 mag. I just took a fine honing stone, and stoned it till I had a small amount of friction on assembly, made4 assembly a little easier. Gonig to the range tomorow, withit for the first time.

Out of the six 92s I bought, one had the same fit as you mention. I treated it just like barracudadave67 did. I've taken mine apart quite a bit so I don't think anything of it anymore. I hunt with them a bunch in high humidity or rain, so everyone of them gets pulled completely apart each year (including the dreaded forearm) and cleaned. I'm working through all of them right now. Nothing to it.

Based on the reports of the newer rifles, the last two years of production, I think after a complete cleaning as described above and in other topics on the forum, I think I would just shoot the rifle and see what you think. It seems that all the springs, whether they are flat or coil, have gotten better.

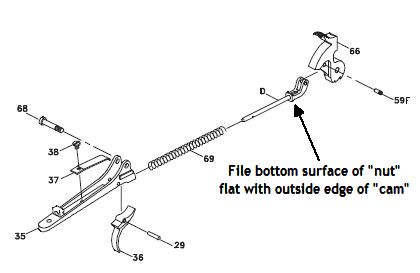

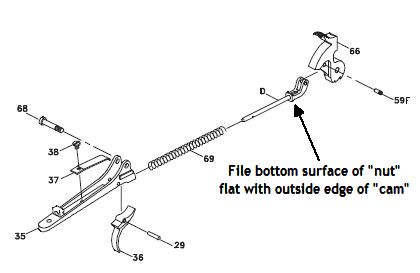

Until I shot a hundred rounds or so out of the rifle about the only thing I would specifically check and dress if necessary, is the bottom of the "nut" up against the cam on the Main Spring Rod (D). At the hammer is cocked and the rod cams over, I have seen the weld between the nut and cam make contact with the Trigger Spring (37). If this happens, you truly cannot evaluate the Main (69) or Trigger Spring.

Two of my rifles had completed contact, even resulting in a bent rod on one rifle. The clearance at the bottom of rod is so close, I flattened the nut with the cam on all my rifles.

Re: tight fit, rought edges everywhere

Posted: 18 May 2016 10:54

by sheepherder

Thank you for the posts and thoughts. 100 rounds in the next couple days in Maine - looking forward to it.

The some 5 minutes of a little bit of attention with flitz on a cleaning patch made a huge difference. One finger smooth action now. Still wonder about a lighter trigger spring.

I smoothed the lever and the bolt stops. The rough edges on the carrier and the curved area on the sides, the trigger sear and the area of the hammer that rides in the bottom tang hole.

The biggest hang up on the reassemble was from how rough the drill hole was on the bottom tang that allows the screw to hold the tang and hammer assembly together. Fits together much easier now.

I'd look to that part if the tang and hammer assembly don't seem to play well with each other

Re: tight fit, rought edges everywhere

Posted: 10 Jun 2016 08:38

by matheda

sheepherder wrote:Every time I missed, I had to tap the lower tang out it was so tightly fit... the last 1/8 inch is still hard.

I just bought mine a few nights ago and had the exact same experience. I was following along with the video and when it got to the part of removing the tang I thought I had missed a screw or done something else wrong, but it was just super tight. I ended up having to give it a few taps with a hard rubber hammer to both remove it and to reinstall it.